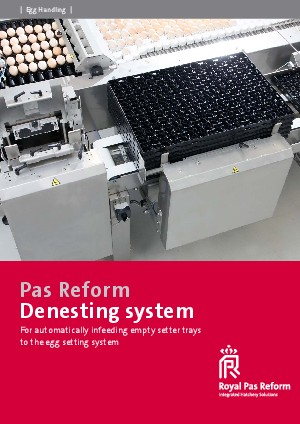

Denesting system

For automatically infeeding empty setter trays to the egg setting system

Benefits

The setter tray denester speeds up the setting process by separating a setter tray from a stack of trays and placing this tray on the egg setting system’s conveyor. Reduces manual labour by automatically positioning the setter tray for egg setting.

Suitable for various kinds of plastic setter trays as well as a separate unit for 30 egg pulp, paper or plastic trays for repacking.

How it works

- A stack of setter trays are manually positioned into the denesting system

- The first (bottom) tray is released and supplied by activating the start button of the denester. After that, the next trays are supplied automatically

- The denester blocks remove one tray from the bottom of the stack of setter trays and place this tray onto the outfeed conveyor

- The last tray of the stack always remains in the denesting system, for easy reloading of a new stack of setter trays

- By combining multiple denester systems, the egg setting system can automatically set eggs on different types of trays, as required

Technical specifications

| Capacity | 200 setter trays/hour or 30,000 eggs/hour |

| Maximum stack height | 30 setter trays / max. 900 mm total height |

| Dimensions (LxW) | 760 x 590 mm |

| Material | Stainless steel AISI304 |

| IP Marking | IP65 |