Incubation times in the modern hatchery

Tags: Hatchery management | Whitepaper

, 9 December 2011

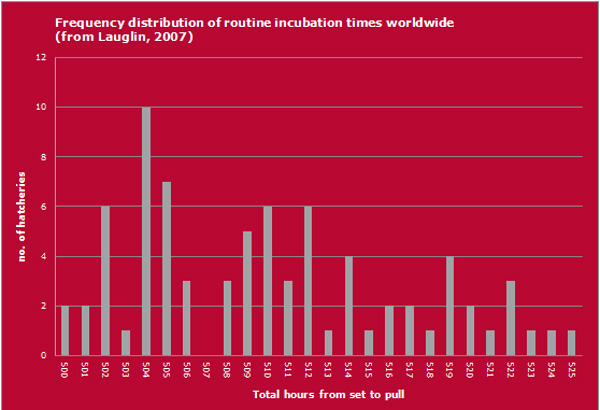

The chicken embryo generally needs 21 days (504 h) to complete incubation, including the drying of down (Etches, 1996). In practice however, incubation periods vary considerably, as observed by Laughlin (2007) in large scale field surveys, which recorded pulling times from the setting of eggs of 500 up to 526 hours (figure 1).

This variation can partly be explained by differences in the time required to heat the eggs from room temperature to incubation temperature (100 ° F), either due to initial egg temperature and/or the different heating capacities of incubator types.

Incubation time also varies because the growth rate of the embryos differs between batches of eggs. Flock age and egg storage are the best-known parameters for influencing embryonic growth rate and, thus, hatching times. As a general rule, eggs stored for more than five days need one hour more incubation time per day of storage.

Eggs from peak production flocks hatch earlier than eggs from younger or older flocks. This observation from practice is confirmed by small scale experiments published in several scientific papers, whereby the average incubation period for different broiler lines varied between 498h for flocks of 35-45 wks of age and 508 h for younger (55 wks) flocks.

There may be two distinct explanations for the shorter incubation time of eggs from peak production flocks. Firstly, higher fertility in these eggs means that the number of heat producing eggs on the single tray is increased. This may result in higher average embryo temperatures, inducing accelerated development and therefore an early hatch. Secondly, hens in peak production are of optimum physiological reproductive age. They produce good quality eggs and embryos that grow at an optimum rate, which may result in an early hatch.

Single stage incubation enables the finite control of embryo temperature and thus hatching time. In contrast to the management of incubation temperature, the opportunity to influence egg specific factors, such as flock age or egg size, is limited. However, based on experience, the hatchery manager can tailor egg specific programs using single-stage incubation.

Knowing the correct incubation time from setting to hatching is important for planning optimized chick take-off. In practice, incubation times can vary not only between different hatcheries – but also within hatcheries, between different batches. Pulling times and future setting-times, should therefore be fine-tuned based on observation – making an observation-window a very practical and useful feature in the hatcher.

Optimal pulling time can also be shown on the display of the hatcher, when this feature is available, using software that reads the naturally evolving humidity peak inside the hatcher to trigger a so called ‘hatch alert’.

For optimal chick quality, pulling should occur when 90-95% of the chicks are completely dry, with 5-10 % almost dry except at the neck. Chicks collected at the optimum time point show no signs of dehydration or feather development, while dehydrated chicks are inactive, with thin legs and dry-looking scales.

Advice

- Pull chicks at the correct time for optimum chick quality.

- Plan the start of the incubation cycle such that chicks are ready for take off at 504 ± 2 h. Accommodate variance in hatching times within and between hatcheries.

- Decide on the actual take-off time by observing the hatched chicks at 500 hours. This is especially important when fresh eggs from peak production flocks are incubated;

- Be flexible in choosing the first hatcher to be pulled: trust observation over routine. When i5-10% of the chicks in a tray are still wet around the neck, the hatch is ready for take-off;

- Adjust setting times for subsequent cycles based on continuous observation and data analysis from previous incubation cycles, taking egg type, flock age and storage time into consideration.

Written by Dr. Marleen Boerjan

We welcome your feedback on this article - and if you require any additional information, please don't hesitate to contact Pas Reform Academy.