This recent addition now makes Spelderholt a self-contained, fully-comprehensive research facility covering all aspects of breeder, incubation and commercial broiler performance. Previously owned and run by Livestock Research Wageningen UR, the Spelderholt facilities opened in 2003 but closed in early 2012. Aviagen then took on the buildings on a long term lease, boosting its global R & D capabilities.

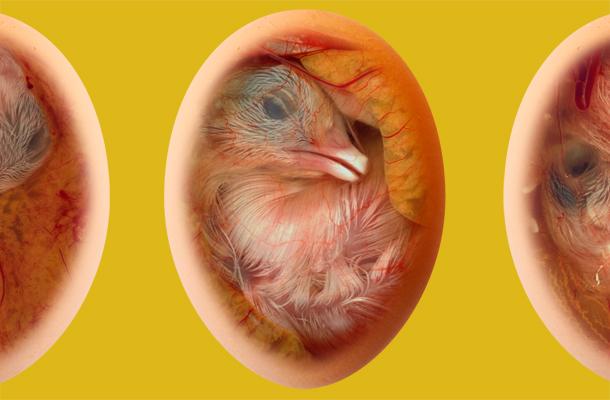

For the new hatchery, Aviagen worked closely with Pas Reform to design a suitable hatchery to set and hatch the eggs produced in the breeder trials houses every week, as well as to provide suitable facilities to run trials of egg storage, egg hygiene and incubation conditions. The new hatchery boasts SmartSetPro™ setters and SmartHatchPro™ hatchers. The facility will allow weekly single stage setting of eggs for trials from on-site production facilities.

Other additions to the new Spelderholt hatchery include egg disinfection facilities, two separately controlled storage rooms for hatching eggs, an egg quality and breakout room, transfer facilities and take off, dispatch and cleaning room. Full shower ‘in and out’ facilities have also been installed for the new hatchery, meeting required biosecurity standards.

Jim McAdam, UK Breeding Programme Director said: “The Spelderholt facilities offer a unique opportunity to investigate the production, environmental and welfare impact of slower-growing alternative products in addition to the more traditional and well known brands.

As a company, we invest heavily in research and are always looking to find ways in which we can improve our R&D offering. The set-up of Spelderholt allows us to replicate conditions and monitor performance across the entire poultry production chain. The addition of these facilities to our current resources is therefore a real boost not only to Aviagen but also to our customers.”

Just prior to completion of the hatchery works there was a great opportunity for students at the Aviagen EMEA Hatchery School, which also took place in the Netherlands, to get a first-hand look at the facility and see some of the key developments in incubation technology as well as getting advice on best practise within a hatchery environment.