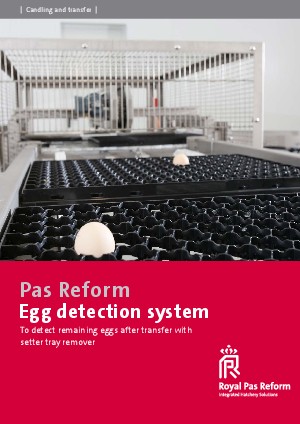

Egg detection system

To detect remaining eggs after transfer with setter tray remover

Benefits

Any eggs left in the setter trays after transfer are detected, before the trays move on to a setter tray stacker or washing machine. This prevents setter trays with stuck or large egg shell remains from entering into the washer, improving hygiene and minimising debris inside the washing machine. Egg remains are manually and easily cleared from the trays, which are then returned inline to the washing machine conveyor.

How it works

- The system automatically detects any remaining eggs from each position in the setter tray

- Setter trays with remaining eggs are automatically diverted to a separate belt

- Here the remaining eggs are removed manually

- The trays are then returned to the conveyor system for transport to the washer

Technical specifications

| Capacity | Up to 600 trays per hour |

| Max. Power consumption | 2.4 kW |

| Air consumption | 10 litre/min at 6 bar |

| Dimensions (LxBxH) | 4700 x 4000 x 1500 mm |

| Weight | 700 kg |

| IP Marking | Motors IP55, Sensors IP68 / IP69K, Control panel IP66 |