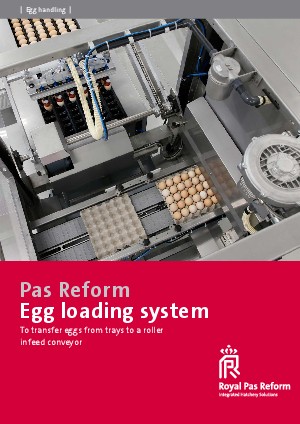

Egg loading system

Transfer eggs from trays to a roller infeed conveyor

Benefits

In the egg loading system the eggs are placed from transport trays onto the infeed roller - or belt conveyor of the egg setting line. The hatching eggs are protected against hairline cracks by the the gentle movement of the vacuum transfer head. The durable suction cups easily and securely transfer the eggs by means of vacuum. Even the presence of small feather or any other dirt does not influence this process. The system works with plastic or cardboard trays.

How it works

- Transport trays are supplied to and removed from the egg loading system by transport conveyors (supply conveyor, transfer conveyor, discharge conveyor)

- The vacuum head of the egg loading system moves towards the tray with eggs and the vacuum switches on automatically to pick-up the eggs

- The vacuum head moves the eggs to the roller track or belt conveyor, where the vacuum switches off to place the eggs gently on the egg setting line

- As long as trays arrive underneath the system loader this sequence is repeated automatically

Technical specifications

| Capacity | 30,000 eggs/hr |

| Installed power | 2.24 kW |

| Air requirement | 25 litre/min at 8 bar |

| Dimensions | 1440 x 1000 x 1850 mm |

| Weight | 450 Kg |

| Material IP | Stainless steel AISI304 with durable plastic conveyor belt |

| Marking | IP65 |