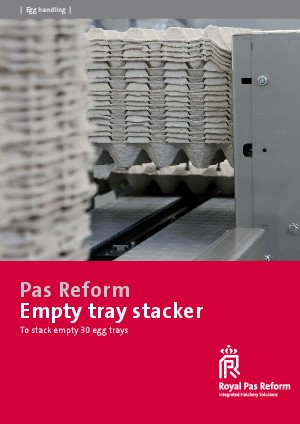

Empty tray stacker

To stack empty 30 egg trays

Benefits

Empty 30 egg trays are automatically transferred to the empty tray stacker that stacks them. Stacks of empty trays are released and transferred to the end of the empty tray conveyor, where they can be manually removed for further processing. Maximum stack height is easily adjustable via the operating panel. Reduces manual labour and is suitable for both pulp and plastic trays.

How it works

- Empty 30 egg trays are supplied by the empty tray conveyor

- As soon as a tray is positioned above the pusher pins, one complete stroke lifts the tray from the belt and pushes it through the grippers

- While continuing the stroke, the pins move down again and stop underneath the empty tray conveyor

- This sequence is repeated as long as trays are supplied by the empty tray conveyor

- When the maximum stack height (maximum number of trays in the empty tray stacker) is reached, the pusher pins move up. When they are in the top position they stop, the grippers move in, and the pusher pins move down again, lowering the stack of trays onto the empty tray conveyor

- The stack of trays moves automatically to the end of the empty tray conveyor, where it can be manually removed

Technical specifications

| Capacity | 1,300 trays/hour or 40,000 eggs per hour |

| Maximum stack height | 80 paper or 50 plastic egg trays |

| Installed power | 0.2 kW |

| IP Marking | IP65 |

| Material | Stainless steel AISI304 |

| Dimensions (LxW) | 400 x 400 mm |

| Weight | 25 Kg |

| Including | Automatic stack release system for further transport |