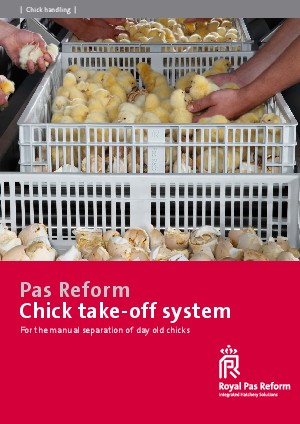

Chick take-off system

For the manual separation of day old chicks

Benefits

Ergonomically designed, Pas Reform’s take-off system provides good, comfortable access for up to eight operators to transfer chicks manually from hatcher baskets to an integrated discharge conveyor. Designed with optimum hygiene in mind, the high quality stainless steel design is easily cleaned while the roller conveyor ensures the smooth transportation of full hatcher baskets. Available in two sizes, for 4 or 8 operators.

How it works

- Full hatcher baskets with chicks and debris are manually or automatically positioned on the take-off table

- Operators manually take-off the chicks, leaving waste and debris in the hatcher basket

- Chicks are transported via an integrated chute onto a belt conveyor for further handling

- Conveyor belt is available with flexible discharge positions

Technical specifications

| 4 persons take-off system | 40,000 chicks/hour capacity (Estimate, based on 10,000 chicks per operator per hour) |

| 8 persons take-off system | 80,000 chicks/hour capacity (Estimate, based on 10,000 chicks per operator per hour) |

| Length chick coveryor | 2.8 Meters |

| Width roller conveyor | 600 mm |

| Width | 1080 mm |

| Height | 930 mm (50 mm adjustable) |

| Material | Stainless steel AISI304 (where applicable) |

| Including | Flexible positionable chick discharge conveyor |