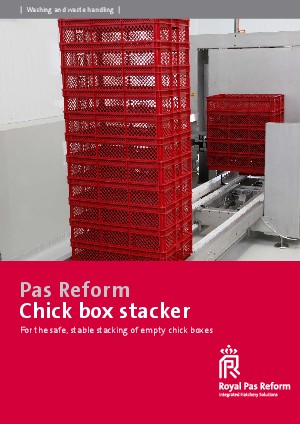

Chick box stacker

For the safe, steady stacking of empty chick boxes

Benefits

For the safe, steady stacking of empty chick boxes directly from chain conveyor. Automatically stacks the boxes prior to positioning into the stoare area. Easy to run and operator friendly, the stacker is easily maintained for long life and easy to clean using high pressure equipment. Typically used at the end of a chick box washing line, it design is based on smooth and controlled stacking of chick boxes and it IP Marking allows for wet boxes to be handled with this unit, prior to drying and storage.

How it works

- Empty chick boxes after washing individually transported into the stacker

- As soon as a box arrives inside the stacking unit, this box is lifted, so the next chick box can be transported underneath this box.

- The lifted chick box is then placed carefully on top of the lowest chick box on the conveyor belt, followed by lifting the bottom box, together with the previous stacked boxes entirely above the conveyor again

- This operation is repeated untill the desired height of stacked boxes has been achieved. At this point, the entire stack is released for further transport on the discharge conveyor

Technical specifications

| Capacity | up to 1,000 chick boxes/hour |

| Max. lifting capacity | 250 kg |

| Installed power | 7 kVA |

| Air consumption | 2,0 m3/hour at 8 bar |

| Dimensions (LxWxH) | 1.648 x 1.600 x 1.635 mm (excl. conveyors and manual loading station) |

| Material | Constructed of stainless steel AISI304 for easy cleaning with high-pressure equipment |

| Including | Easy operating control unit and adjustable stack height. |