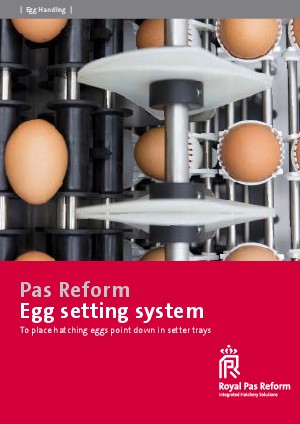

Egg setting system

To place hatching eggs point down in setter trays

Benefits

Solid, reliable system for placing eggs onto setter trays combines gentle egg handling with 99.7 per cent point down setting to maximize hatchability. Automatic setter tray destacking and loading pressure sensor to control egg infeed, as well as a double egg sensor to detect remaining eggs between the roller track and the cup conveyor. Eggs can be set both on matrix (SmartTray™ 150) and on honeycomb (SmartTray™ 162) structured trays. An extra tray denester for 30 egg trays can be supplied to repack the eggs after point down correction, for transport to other locations.

How it works

- Place eggs manually or automatically on the infeed conveyor – Automatic infeed control sensors on the sides of the conveyor prevent the accumulation of eggs on the infeed conveyor

- Infeed gates detect every egg loaded into the system. When all the gates have detected an egg, the roller track moves one step forward, receiving the eggs from the gates between 2 roller shafts on the roller track

- A rotating movement during each step forward moves the eggs with their pointed ends towards the outside of the rollers

- At the end of the roller conveyor, tipping pins tip the eggs point down into the cups, while flaps guide the eggs

- The cup conveyor transports the eggs towards the transfer position until the first line of eggs is detected by the start transfer sensor

- The vacuum head on the transfer lever moves down to pick up the eggs and transports them towards an empty setter tray on the output conveyor

- If required, a special gate closing system can create various patterns of cups filled with eggs for special types of setter trays

Technical specifications

| Capacity | 30,000 eggs/hr |

| Accuracy | 99.7% point down setting |

| Maximum egg size (LxD) | 76 x 52 mm |

| Installed power | 1.8 kW |

| Air Requirement | 15 ltr/min at 8 bar |

| Material | Stainless steel AISI304 (where applicable) |

| Dimensions | 4100 x 1500 x 900 mm |

| Weight | 500 Kg |

| IP Marking | IP65 |