Egg grading system

To weigh and grade eggs into four different user defined sizes

Benefits

Electronically weighs and grades up to four different user defined egg sizes, divided over two or three separate exits. Reducing the weight difference of the eggs per trolley and sorting specific hatching egg sizes to suit specific incubation programs or processes increases hatchability and chick uniformity. By sorting out non-hatching eggs based on weight, this grader also ensures maximum efficiency in the incubators.

A touch screen control panel displays crucial statistical information, including egg numbers per breeder farm in a specific weight range. Data can be retrieved via the integrated USB port and provides useful information for keeping track of the entire flock’s performance.

How it works

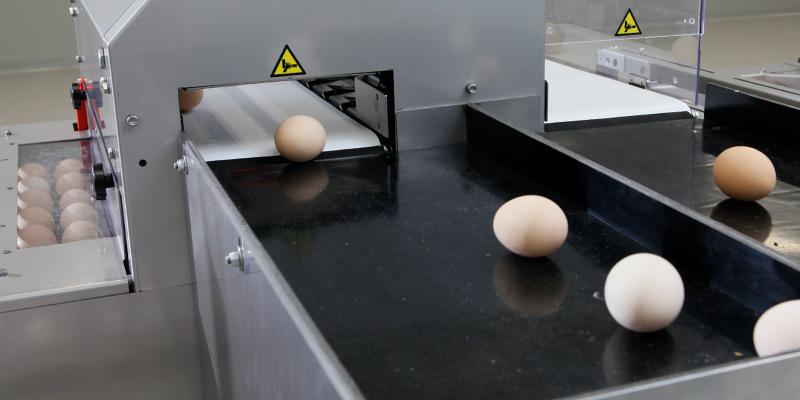

- Eggs enter the egg grader via an infeed conveyor, where oversized, misshapen, cracked or dirty eggs can be removed

- The system uses electronic weighing units, grading the eggs into a maximum of four user defined sizes/weight classes (eg: S, M, L and XL)

- Most eggs are routed to the connected egg setting (packing) system

- Non-hatching eggs are separated and routed automatically to the hand packing table for manual collection or optionally to another egg setting system, for separate incubation of various egg sizes

Technical specifications

| Capacity | 30,000 eggs per hour |

| Accuracy | +/- 0.5 gram |

| Max. egg size (LxD) | 76 x 52 mm |

| Installed power | 0.4 kW |

| Air requirement | 100 ltr/min at 8 bar |

| Weight classes | 3 or 4 |

| Number of exits | 2 or 3 |

| Dimensions (LxWxH) | 1950 x 1000 x 1500 mm |

| Weight | 200 Kg |

| IP Marking | IP65 |

| Optional | Additional egg setting system for automatic setting of second weight class (4 weight class grader only). |