SmartSense™ NF Setter

Adaptive embryonic incubation

Benefits

SmartSense™ uses a next generation series of intelligent, high-accuracy sensors for both adaptive incubator control and predictive process information. This results in ongoing optimisation of the incubation process, for the highest numbers of best-quality chicks.

How it works

Adaptive embryonic incubation

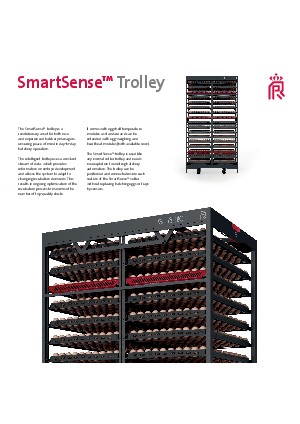

SmartSense™, with its industry leading, precise climate control - based on air temperature, relative humidity and CO2 – also features a next generation series of intelligent, high-accuracy sensors in the SmartSense™ trolley. These constantly and non-invasively measure temperature, together with egg weight loss and heart rate averages (both available soon). The result is that the incubator can automatically adapt the environmental conditions to the actual needs of the growing embryos, further optimising uniformity and maximising post-hatch performance.

The full SmartSense™ incubation series comprises the SmartSense™ setter and SmartSense™ hatcher, combined with the SmartSense™ trolley, SmartSense™ interface and SmartCenterPro™ hatchery management system.

Modular single-stage incubation

The modular design of the SmartSense™ single-stage incubation series allows you to carefully manage the conditions required by the developing embryos in each fan tower zone. By controlling each zone individually, a range of incubation environments can be created to meet the specific needs of each egg, according to breed, flock, age or storage profile.

Together with the SmartSense™ trolley, the system automatically adapts to specific embryonic needs. The result is maximum uniformity and optimal climate conditions for each batch of eggs at every stage of the incubation process - making specific trolley positioning and transfer redundant.

Technical specifications

| Number of setter trolleys | 4, 8, 12, 18 or 24 |

| 36 egg tray / 15 high trolley | Capacity up to 103,680 hen eggs |

| 42 egg tray / 15 high trolley | Capacity up to 120,960 hen eggs |

| 84 (SST) egg tray / 16 high trolley | Capacity up to 129,024 hen eggs |

| 54 egg tray / 16 high trolley | Capacity up to 124,416 hen eggs |

| 54 egg tray / 17 high trolley | Capacity up to 132,192 hen eggs |

| 165 egg tray / 16 high trolley | Capacity up to 126,720 hen eggs |

| 165 egg tray / 17 high trolley | Capacity up to 136,640 hen eggs |

| Modular design | Heating, cooling, humidification (optional) and ventilation systems in each fan tower zone |

| Heating | Electrical heating per fan tower (integrated heating optional) |

| Cooling | Water cooling system with double coil circular cooling system™ per fan tower zone |

| Humidification (optional) | Pressurized Air + Water fogging nozzle per fan tower zone |

| Ventilation | Double blade fan system per incubator fan tower; Gasketed, carburetor-style intake and exhaust vents for totally sealed machine and calibrated/controlled ventilation rates |

| Set points per zone | Separate temperature set points for each fan tower zone |

| Incubator control | SmartSense™ user interface |

| AEI™ (optional) | Adaptive Embryonic Incubation™ (available soon) |

| ESM™ | Energy Saving Module™, for fully programmable RPM of the fans |

| AMF™ | Adaptive Metabolic Feedback™, with high precision humidity and CO2 control |