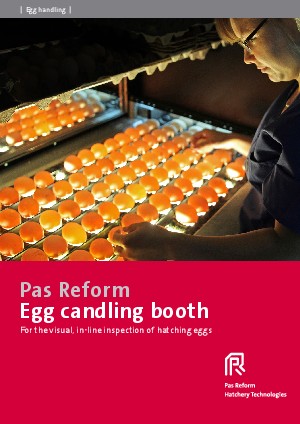

Egg candling booth

For the visual, in-line inspection of hatching eggs

Benefits

In-line inspection system for the reliable detection of cracks in hatching eggs prior to setting. The automatic turning rollers ensure that eggs can be inspected from all sides and poor quality eggs can be manually removed. The traying shelf inside the cabin can hold 30 egg pulp or plastic trays for the removed eggs. A dark curtain limits the influence of surrounding light into the candling booth during operation.

How it works

- Eggs are manually or automatically transferred onto a roller conveyor

- A roller conveyor transfers the eggs along a stainless steel light conductor underneath the machine

- Each egg is rotated to enable fast, accurate inspection for cracks or defects

- Poor quality eggs are manually removed from the conveyor

- Suitable for one or two person operation

Technical specifications

| Capacity | 30,000 eggs/hour with 2 operators |

| Installed power | 0.2 kW |

| Material | Stainless steel AISI 304 (where applicable) |

| Dimensions (LxBxH) | 1.550 x 700 x 2.200 mm |

| Weight | 300 kg |

| IP Marking | IP65 |

| Including | Durable energy saving LED lights |