Egg transfer system

For the semi-automated transfer of hatching

Benefits

Semi-automatically transferring eggs from setter tray to hatcher basket improves operator speed, efficiency and performance. The quick coupling suction head allows for an easy changeover to other tray types, while the semi-automated egg transfer system emits low sound levels for quiet running and is easy to clean.

With a capacity of up to 50,000 eggs per hour, this system is easily combined with automatic candling and take-out machines. Four wheels for stability and easy manoeuvrability. A useful back-up for automatic transfer systems.

How it works

- A full setter tray is loaded into the system by operator or automatic conveyor

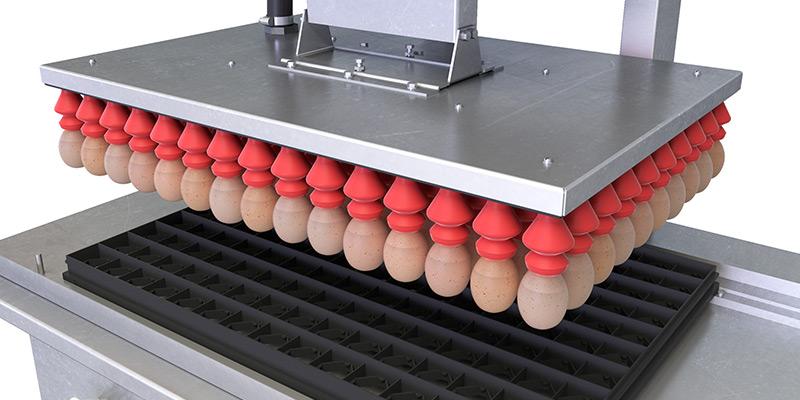

- Eggs from the setter tray are transferred by a vertical suction head that descends after positioning the tray, to gently lift the eggs by vacuum suction

- The empty setter tray can be removed and replaced by an empty hatcher basket placed underneath the vacuum suction head with eggs

- The head gently lowers the eggs into position in the hatcher basket, after which the full basket can be removed

- This sequence is repeated until transfer of all the eggs is complete

Technical specifications

| Capacity | 50,000 hatching eggs/hour (depending on the amount of operators) |

| Personnel | Operated by one or multiple operators alternately placing a full setter tray and an empty hatcher basket |

| Power consumption | 0.8 kW |

| Material | Stainless steel AISI304, mounted on large swivel castors for easy transport |

| Dimensions (LxWxH) | 1210 x 790 x 1840 mm |

| Weight | 172 kg |