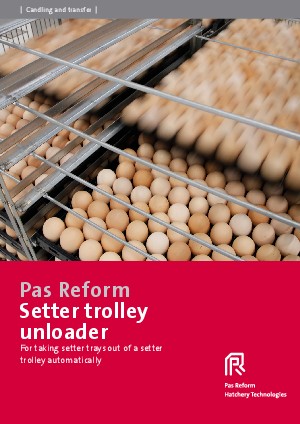

Setter trolley unloader

For taking setter trays out of a setter trolley automatically

Benefits

The fully automatic trolley unloader substitutes the heavy and repetitive manual labour of unloading setter trays from trolleys. With a smooth action that prevents damage to the hatching eggs, the trolley unloader’s double bed principle enables two setter trays to be unloaded at a time, to allow maximum capacity while maintaining a smooth, careful operation.

The specially developed locking system allows the trolley to be easily placed into the unloader, with a quick release mechanism for the removal of the trolley when it is empty. Compact design requires minimum floor space, with versions available for both 16 and 17 tray-high setter trolleys.

How it works

- A setter trolley loaded with trays is positioned in front of the unloader with the locking system closed

- Two setter trays are pulled out of the setter trolley onto the automatic trolley unloading unit at a time

- The automatic feeder puts each setter tray onto a conveyor and indexes automatically to the next unloading height

- As unloading is always positioned on one side of the trolley, batches remain unmixed

- The trolley remains fixed and static throughout the entire operation

- When all the trays have been removed, the empty trolley is replaced with another full trolley by an operator

Technical specifications

| Capacity | 600 setter trays/hour (90,000 eggs per hour) depending on trolley transfer time |

| Installed power | 6 kVA |

| Air consumption | 1.6 m3/hour at 6 bar |

| Material | Stainless steel AISI304 (where applicable) |

| Dimensions | 3200 x 2200 x 2400 mm |

| Weight | 800 kg |

| IP Marking | Motors IP55, Sensors IP68/IP69K, Control panel IP66 |