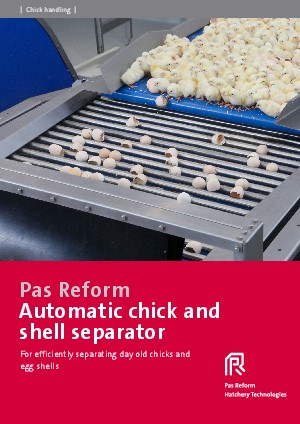

Automatic chick and shell separator

For efficiently separating day old chicks and egg shells

Benefits

Day old chicks are cleanly and efficiently separated from shell, with waste product collected into a hopper to be removed from the building by a waste removal system. By tipping the baskets over the full width onto the conveyor belt, the density of chicks, shells and dead in shell is relatively low. This together with a minimal drop height ensures that the chicks are exposed to the absolute minimum of stress.

A manually adjustable variator enables the speed of the separator to be adjusted for optimised operation in todays modern, highly automated hatchery. In combination with the cyclone vacuum system, maximum separation yield can be achieved, which makes chick quality control on the selection belt much easier and more accurate. Various configurations make the separator suitable for almost every chick handling area.

How it works

- The hatcher basket’s contents - chicks, shells and eggs - are tipped onto a belt conveyor by an automatic tipping system.

- The hatcher baskets are rotated 180 degrees around their central axis, to limit the drop height of the baskets above the central conveyor belt

- The conveyor then transports the chicks, eggs and shells onto a separating roller conveyor bed of stainless steel round tubes

- As the birds spread out across the conveyor, they pass through openings between the rollers onto a belt conveyor, which removes them from the rollers

- This process separates the chicks from any unhatched whole eggs and larger eggshells, which cannot pass through the rollers and are transported to the waste removal system

- A vacuum cyclone system removes the remaining pieces of shell from the conveyor as the chicks are moved to the processing room

- A selection conveyor allows for final inspection and quality control of the day old chicks, prior to further handling

Technical specifications

| Capacity (depending on configuration) | 50,000, 72,000, 90,000 or 120,000 chicks/hour |

| Installed power | 2.6 kW |

| Air requirement | 0.8 litre/min at 7 bar |

| Dimensions | Depending on configuration |

| Weight | Approx. 2,000 kg |

| Including | Cyclone system for efficient egg shell removal |

| Options | Inspection belt for unhatched eggs |