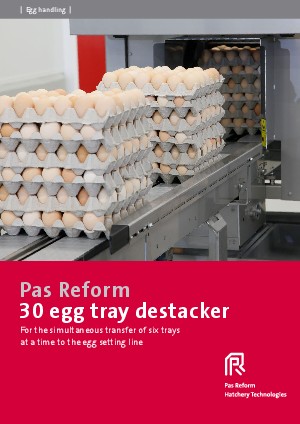

30 egg tray destacker

For the simultaneous transfer of six trays at a time to the egg setting line

Benefits

The tray destacker for stacks of 30 egg trays automatically destacks up to six filled trays (pulp, paper or plastic). Easy single operator use with flexible conveyor for buffer function.

Automatic infeed buffer control for stacks is included. Stacks are turned 90 degrees after every tray for easy and seamless destacking of the entire stack

How it works

- Stacks with a maximum of six 30 egg trays are placed on the supply conveyor, to supply the stacks to the destacker conveyor inside the tray destacking system. Because of the higher speed of this conveyor, the first stack is separated from the other stacks

- As soon as the stack runs against the stoppers in the center of the tray destacking system, the conveyor stops and grippers in the turntable lift the stack up from the second tray in the stack, leaving the first tray on the conveyor

- The stoppers move down and the first tray is transported to the downstream transfer conveyor

- At the same time, the turntable turns the lifted stack 90 degrees and places the stack back on the de-stacker conveyor, leaving the second tray on the conveyor and lifting up the stack again from the third tray

- As soon as the complete stack is destacked, the stoppers move up again and the next stack enters the destacker

Technical specifications

| Capacity | 167 stacks/hour or 30,000 eggs/hour |

| Installed power | 1.52 kW |

| Max. stack height | 6 trays with 30 eggs each |

| Air requirement | 15 ltr/min at 8 bar |

| Dimensions (LxWxH) | 1.200 x 900 x 1.600 mm |

| Weight | 350 kg |

| Material | Stainless steel AISI304 |

| Material | IP65 |