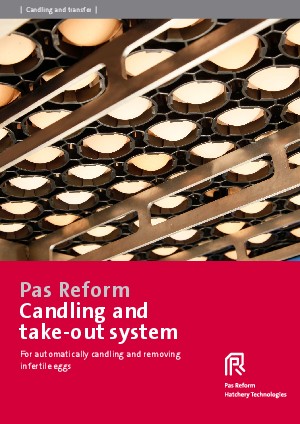

Candling and take-out system

For automatically candling and removing infertile eggs

Benefits

Automatic candling of hatching eggs directly from setter trays identifies the status of eggs on six different levels. Fertile, dead and infertile eggs (clears) are recorded into a database and non-hatching eggs are removed automatically.

Candling data is stored in exportable files, to create valuable fertility information for each batch or hatching egg supplier. Removed eggs can be discharged into a hopper for extraction via a vacuum system, or be transported directly into a waste container. Alternatively, infertile eggs can be manually or automatically packed onto 30 egg trays for alternative saleable use

How it works

- Eggs are automatically transferred in a setter tray via conveyor to the candling area

- The light sensor in the candling unit scans the eggs in the tray to reveal whether eggs are fertile, infertile, early dead, late dead or clear

- This data is recorded into a database for review and reference

- Infertile eggs are automatically removed

- Setter trays with remaining eggs continue for transfer into hatcher baskets

Technical specifications

| Capacity | 90,000 eggs per hour |

| Installed power | 3.4 kW |

| Air consumption | 8.3 litre/min at 7 bar |

| Dimensions (LxWxH) | 2800 x 2370 x 2070 mm (excl. conveyors) |

| Weight | 900 kg |

| Material | Stainless steel AISI304 (where applicable) |

| Candling levels | Embryo (normal developed), embryo (late developed), late dead, early dead, infertile (clear), empty egg position |