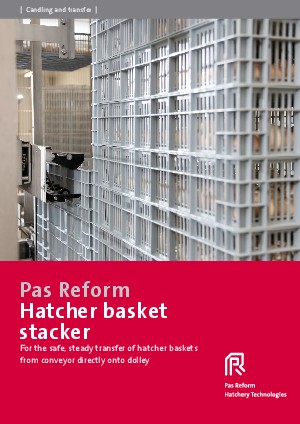

Hatcher basket stacker

For the safe, steady transfer of hatcher baskets from conveyor directly onto dolley

Benefits

Safely stacks full hatcher baskets directly from a conveyor onto the hatcher dolley. By stacking directly on the top of each basket on the dolley, baskets are only touched once and carefully loaded onto the dolley, which reduces the risk of shocks and vibrations. Strong, flexible grippers maintain strong, reliable contact with the hatcher baskets, for the smooth handling of full baskets with valuable hatching eggs inside. The automatic dolley in- and -outfeed system allows for single person operation. By adding more grippers, the capacity of the unit can go up to 720 hatcher baskets per hour. This stacker is easily maintained for long life and easy to clean using high-pressure equipment.

How it works

- A conveyor transports a full hatcher basket with eggs to the stacker

- A dolley is automatically guided into the correct position in the stacker to start the process

- Grippers make a clockwise rotation between the conveyor and the dolley, to place each basket on the top on the dolley

- When both stacks have been stacked, the dolley is automatically pushed out of the stacker, to allow for automatic infeed of a new dolley and maximum continuity

Technical specifications

| Capacity | 580 to 720 baskets per hour |

| Installed power | 4 kW |

| Air consumption | 50 litre/min at 6 bar |

| Dimensions (LxBxH) | 6000 x 1790 x 2840 mm |

| Weight | 1,600 kg |

| Material | Stainless steel AISI304 (where applicable) |

| Including | Automatic dolley infeed and transport system |

| IP Marking | Motors IP55, Sensors IP68/IP69K, Control panel IP66 |