Tipper unit

To automatically empty hatcher baskets

Benefits

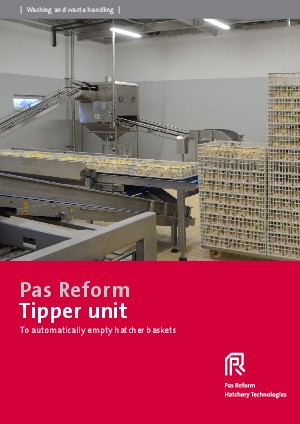

By turning the hatcher basket 180 degrees, the tipper unit’s highly efficient mechanical turning mechanism optimises the disposal of hatcher basket waste. Easy to run, operator friendly and easily maintained, the hatcher basket tipper also delivers high reliability and conserves floor space, with low noise and vibration levels. Both the turning mechanism and the hatcher basket transport belt are located in a sealed stainless steel housing, to retain the majority of dust inside the machine. Suitable for connection to various waste transport systems for the hygienic discharge of residue, the tipper is constructed of stainless steel and easily cleaned with a high pressure washer.

How it works

- With a supply and discharge conveyor, the hatcher basket tipper is situated between the chick take-off system and the hatcher basket washing machine

- The system empties the basket by turning it 180° and tipping its contents into a funnel

- In its upside down position, the hatcher basket is then transported automatically into the hatcher basket washer to be thoroughly cleaned for re-use

- The transport belts prevent any used hatching paper from falling into the funnel. Instead it is deposited in a waste container behind the tipper unit

Technical specifications

| Capacity | Up to 750 hatcher baskets per hour |

| Material | Durable stainless steel AISI304, easy to clean for maximum hygiene |

| Dimensions excl. conveyors (LxW) | 1500 x 1500 mm |

| Dimensions incl. conveyors (LxW) | 3500 x 5550 mm |

| Height | 2600 mm |

| Including | Inclining, easy maintainable infeed conveyor and discharge conveyor |