Air supply plenum

For optimising the air supplied to setters and hatchers

Benefits

The pressurized air supply plenum above the corridor of the setter or hatcher room provides a controlled environment for the pre-conditioning and distribution of air, to deliver increased temperature uniformity and a reduced need for humidification during incubation.

Centralized humidity and temperature control optimises air inlet conditions to the setters and hatchers, for precise, stable air pressure control to the machines, without the influence of pressure changes in the corridor - while at the same time reducing energy consumption and improving the hatchery’s ecological footprint.

The tunnel also improves hygiene when the setters and hatchers are being cleaned, as this air is not mixed with incoming air to other machines.

How it works

- A precise volume of outside air is taken in and pre-conditioned using dedicated air handling units

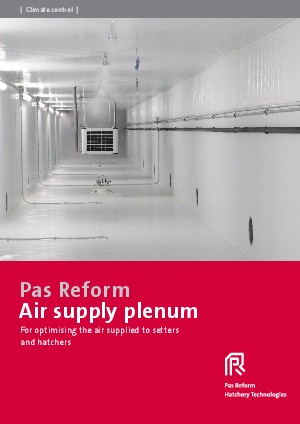

- The pre-conditioned air is then transported via a central air supply duct to the air supply tunnel (plenum) above the setter or hatcher room corridor

- Inside the air supply tunnel (plenum), the air quality is fine-tuned with separate micro controls for temperature, humidity and pressure, to create the precise air quality required for setter or hatcher

- Each incubator is supplied individually and directly from a dedicated tunnel, which prevents the risk of cross-contamination from incoming air

- A central control and communication system for the setter and hatcher rooms monitors and fine-tunes air quality constantly, to optimise the overall operating efficiency of the system

- Temperature uniformity during incubation is optimised, while any risk of cross-contamination is prevented

Technical specifications

| Length | Entire length of the setter or hatcher corridor |

| Width | 2000 mm |

| Height | 1500 mm - 2000 mm |

| Including | Pressure sensor, temperature sensors, humidity sensors, spray nozzle humidifier, room cooler / heater |