Fumigation set for disinfection

To safely release and circulate a disinfectant gas and expel the gas from the building after disinfection

Benefits

Pas Reform’s fumigation set safely releases and circulates formaldehyde gas during fumigation and expels the gas from the building when fumigation is completed. It effectively reduces microbial count on hatching eggs without causing damage to the developing embryo.

Formaldehyde Neutralisation Unit (optional): To ensure that all formaldehyde has been successfully neutralised, a neutralisation unit generates an excess of ammonia vapor. When ammonia comes into contact with any remaining formaldehyde, the resulting chemical reaction produces hexamethylene tetramine, a harmless compound. Any excess ammonia is readily removed by ventilation and the FNU vaporisation method generates ‘dry’ ammonia gas, to prevent the eggs from becoming wet.

How it works

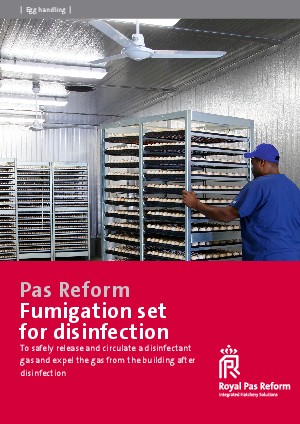

- The disinfection room forms a separation between the ‘dirty’ area and the clean side of hatchery

- Egg trolleys are driven into the airtight fumigation room, equipped with mixing fans to circulate the formaldehyde gas over the eggs during fumigation, an exhaust fan expel the gas from the building when fumigation is completed

- Egg trolleys are placed in a manner which will permit air circulation and exposure to the formaldehyde gas

- After loading is completed, the door of the fumigation room is closed and locked and fumigation can begin by pressing the start button (while fumigation is in progress, a red light will show on both sides of the disinfection room)

- To release formaldehyde gas from paraformaldehyde, a fumigation pan with thermostatically controlled heating device is used. The fumigation pan is heated to evaporate formalin, while ceiling fans circulate to ensure that fumigation reaches every hatching egg

- When fumigation is complete (after appr. 20 minutes), the pan stops heating, an exhaust fan starts up to expel the gas from the building and an automatic air inlet on the clean side of the room opens to let clean air in.

- After appr. 15 minutes the exhaust fan stops and the air inlet closes. A formaldehyde neutralisation unit (optional) then starts the neutralisation process

- After appr. 15 minutes neutralisation stops, the exhaust fan starts again and the air inlet opens again (with ceiling fans still running)

- After a further 15 minutes the process is complete. All equipment stops and the door on the clean side unlocks automatically. The green light shows to indicate that it is time to unload the room.

Technical specifications

| Fumigation set includes | 2 ceiling fans for optimum mixing of formaldehyde > |

| Exhaust fan, 3,000 m3/h capacity | |

| Servo motor controlled air inlet, automatically controlled door locks | |

| Control for fumigation room and fumigation pan | |

| Formaldehyde Neutralisation Unit (optional) | Electrical requirements: 230 Volts, 50 Hz, 1 Ph + 0 + PE |

| Power consumption: 0.37 kW | |

| Dimensions (LxWxH): 750 x 450 x 980 mm |